Our Story

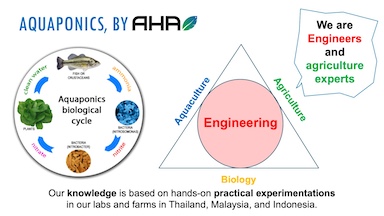

In 2015, a team of visionary individuals set out on a mission to optimize the Aquaponics farming processes. We firmly believed that a nutritious diet was the most effective approach to addressing human health concerns.

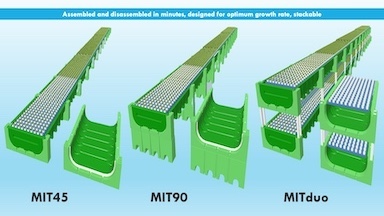

Emulating the Apple model, we focused on designing equipment that not only simplifies the process but also enhances its efficiency and accessibility.

In order to gain access to third-party suppliers, we established AHAS Company. We invested numerous years in testing our ideas, optimizing our equipment, and developing modeling software before commercializing our technology.

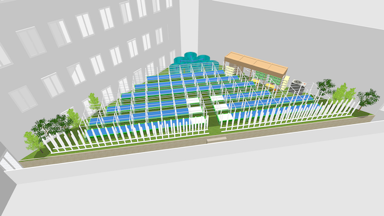

Our technolgy caters to the needs of everyone seeking to cultivate fresh, wholesome, and delectable produce. We take great pride in providing a sustainable farming solution that will usher in a greener and more sustainable future for the world.