Farm Production planning

Maximize farm production

Production planning process

In our aquaponics farms, we harvest every day and we seed every week.

To ensure that your farm will yield the crops required in eight weeks, it is imperative to meticulously plan the desired production and sow the seeds today for the harvest that will be needed at the appropriate time.

Ceres, our Aquaponics Modeling Software, accurately calculates productivity for a wide range of plant species. Ceres is regularly updated with comprehensive production data from all our units for each crop. Given that all our farms are designed with environmental control measures, and that our recommended techniques are diligently adhered to, the predicted productivity closely aligns with actual output.

The production planning process commences by defining the diverse crops and their corresponding quantities. Subsequently, the allocated production area for each plant is determined. Finally, an assessment schedule for each plant is defined.

Should you need our assistance with designing your farm based on your desired production, please email us this form:

Space allocation

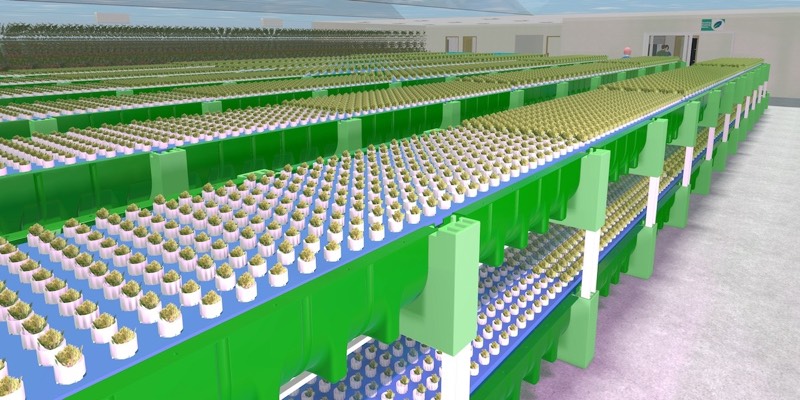

To optimize unit production, it is crucial to maximize the utilization of available growing space. This can be achieved by placing smaller plants at a higher density compared to larger plants, thereby ensuring the most efficient utilization of the available space.

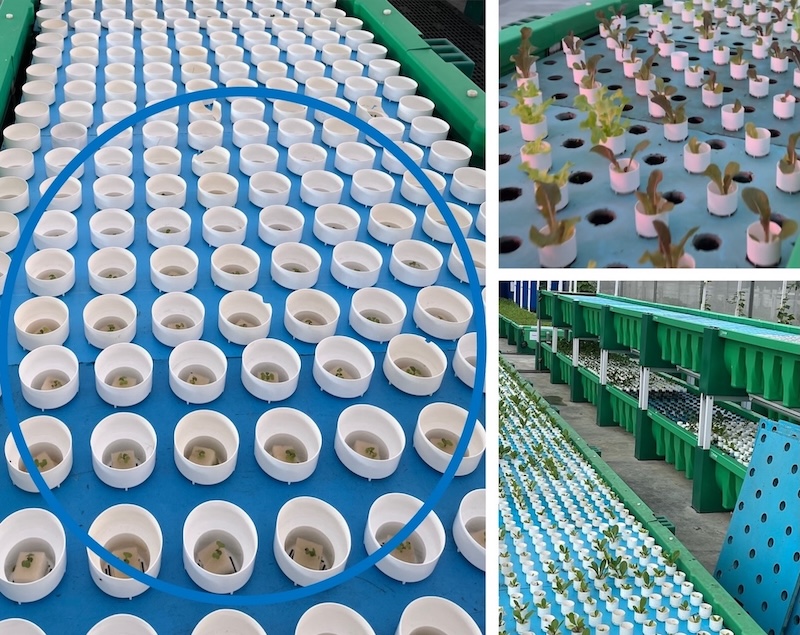

From the germinator, the sponge blocks are placed in pots, and 160 pots are arranged in high-density AHA trays (60x90cm) in the nursery.

Once the plants reach a size that exceeds the nursery spacing capacity, they are transferred to the MIT production lines, where 60 plants are placed on each AHA board (60x90cm).

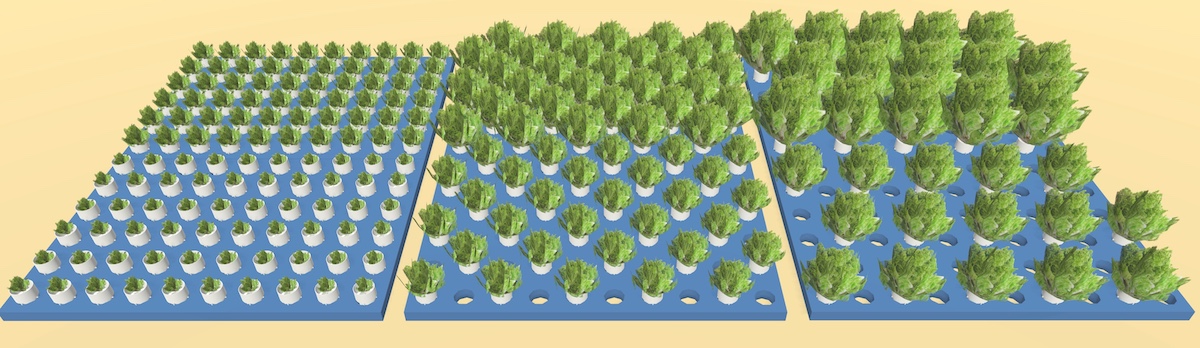

When the plants come into contact with each other again, and we intend for them to grow larger, the 60-pot board is divided into two 30-pot boards.

For extremely large plants, the board is further divided into two 15-pot boards, then eight-pot boards, depending on the desired final size.

Our modeling software, Ceres, calculates a spacing allocation and a seeding requirement for each plant.

Based on the selected plant and the desired maximum plant weight, the growing area is divided into two to four age sections to optimize production. Ceres then advises the number of weekly seedlings required.

Plants are harvested as required in the mature plant section to make space for new plants.

Do's and Don'ts

Any question?