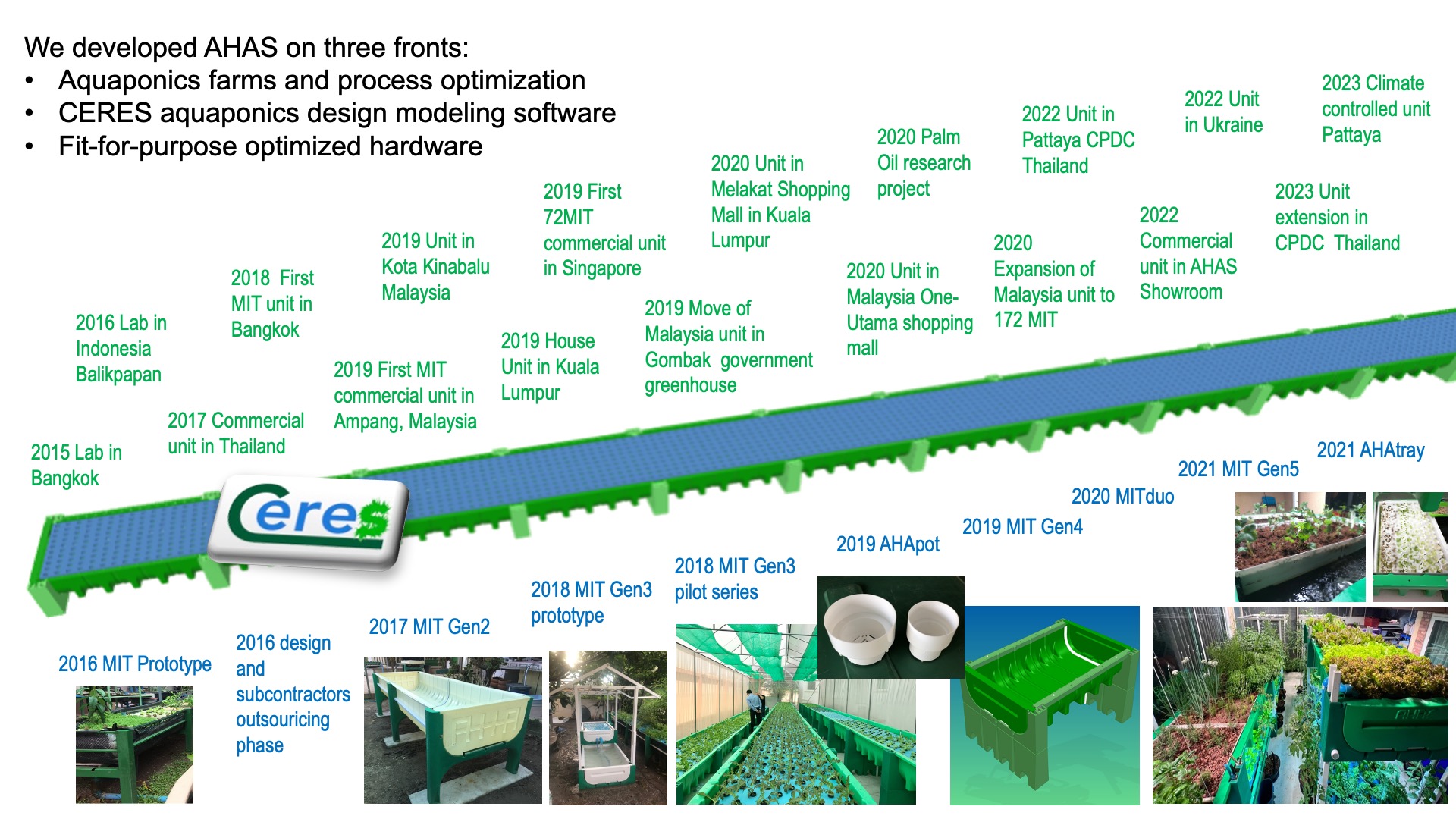

Our Story

AHA was founded in 2015 when French engineer, Regis Vincent, took upon the task of learning and optimizing the Aquaponics farming processes. The AHA concept was then created in order to provide people with efficient, reliable, and high-quality aquaponics designs and services. We want to make it possible for anyone across the world to have access to fresh, healthy, . We are proud to represent sustainable farming practices that will change the world for a greener future.