Aquaponics Systems

Grow you knowledge

Water testing

Unit startup

When starting the unit, a water test should be done daily to ensure the system is ramping up with Nitrates while maintaining the fish's safety. Then, tests can be spaced out to weekly or monthly. Aquaponics is very stable and does not require continuous monitoring.

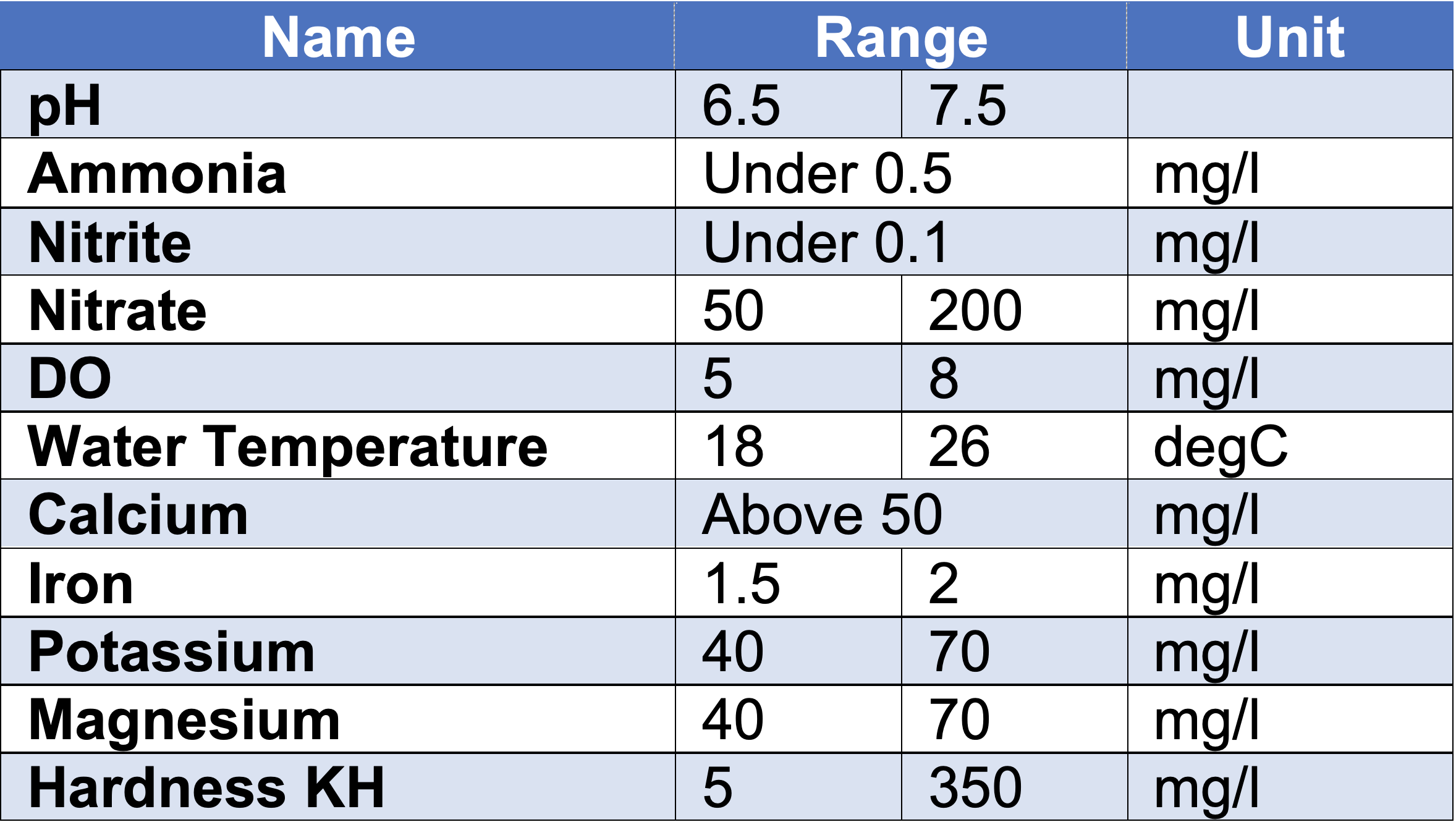

Test for pH, Ammonia, Nitrite, and Nitrates.

After 10 days

Daily test: pH.

Maintain pH between 6.5 and 7.5. The optimum pH range for aquaponics is 6.8 to 7.

To raise the pH, add AHAmix or calcium carbonate.

To reduce the pH, use nitric acid. Do not use citric acid as this is anti-bacterial and will kill the bacteria in your system.

Weekly tes: Iron

Maintain Iron between 1.5mg/l and 2 mg/l

To increase iron, add AHAmix

Other tests which are also important but not essential if you use AHAmix. These tests include Potassium, Magnesium, and Phosphorous.

AHAMix

The AHAmix container several minerals including Iron, Potassium, Magnesium, Phosphate, and Calcium.

Targeted water mineral content

Maintain the water mineral content within these levels

Equipment Maintenance

MIT

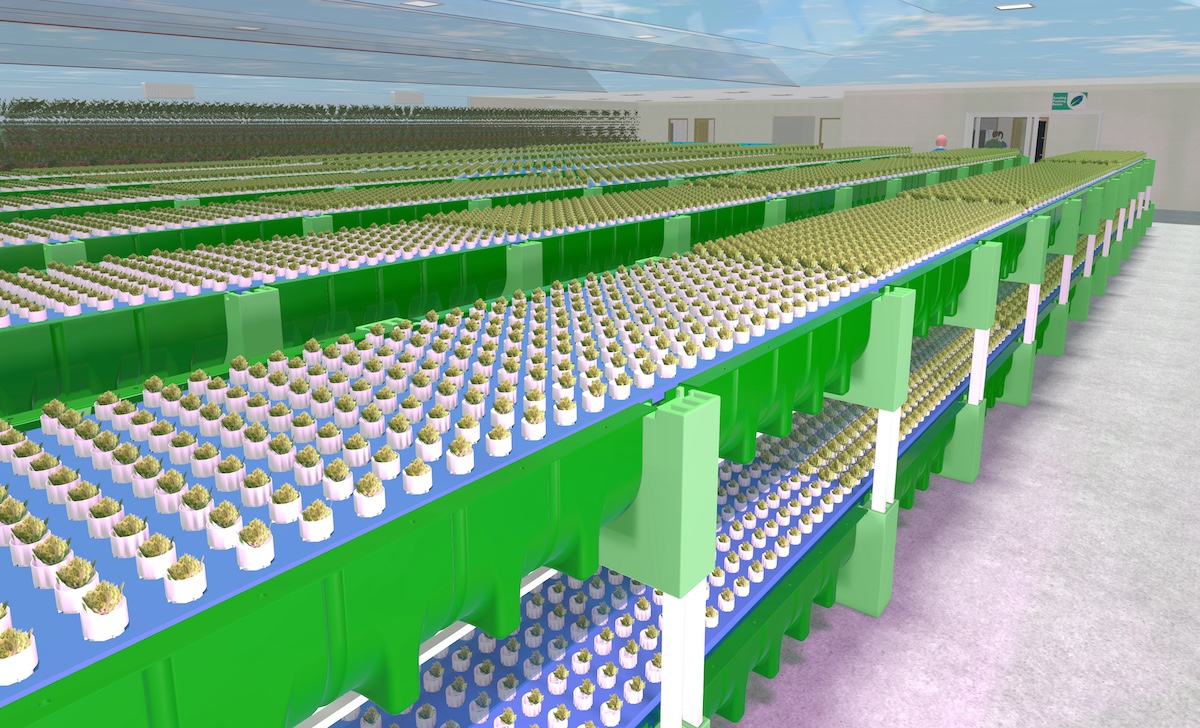

The most likely only maintenance you will have to do in the MIT beds is cleaning.

It is highly recommended to install your system on a cemented floor. If the system is installed on cement slabs on soft ground, the MIT might slightly move, and a seal could slightly pop out by one locking dent. If a slight leak is observed, check the inner seal is fully engaged in the outer seal by pushing the middle of the inner seal into the outer seal all along the seal.

Filter

The filters have blue mesh inside them. These capture fine debris not caught in the filtration and bio-treatment system. These are self-cleaning but may have to be washed after a few years of operation if a high difference in water level is observed before and after the filter.

Procedure.

- Remove the top lock bar of the filter.

- Holding the green filter casing firmly so that it doesn’t move

- Pull out the blue mesh.

- Wash the mesh with a water hose and replace it.

- Repeat the process for the other side.

Water Pump

The water pumps are 24V DC pumps and have been chosen for safety and performance for your system. These pumps have small ceramic impellors and typically last for years.

Suppose you see or hear any anomalies in your pump. Please proceed with the following.

- Disconnect the electric supply.

- Remove the filter from the end of the pump and check for any debris. Remove as required.

- Rotate the motor anticlockwise, opening the pump to view the impellor. Check for wear and debris.

- You can further pull the impellor and rotor from the pump body and inspect them.

- Once everything has been checked, replace all parts in reverse order.

- If new or worn parts are required, then replace the pump. There is an O-ring between the plastic housing and the impellor. Ensure that it is positioned between these parts correctly.

Service your pumps monthly.

Air Blower and air pump

Blowers and air pumps are sealed units. In case of failure, please replace it with a new one. They usually last for three years.

Micro bubble air hose

The microbubble air hose lasts about two years.

You can clean the air hose with your hand or a nylon brush over the pipe. Any debris plugged or settled in the hose will be removed. Complete this task with the air pump on. Otherwise, you will compress the debris even more into the microbubble hose.

Ensure the hose is locked in the holder at the bottom of the MIT.

Production planning

It is critical to plan the desired production ahead and seed today what will be harvested in eight weeks.

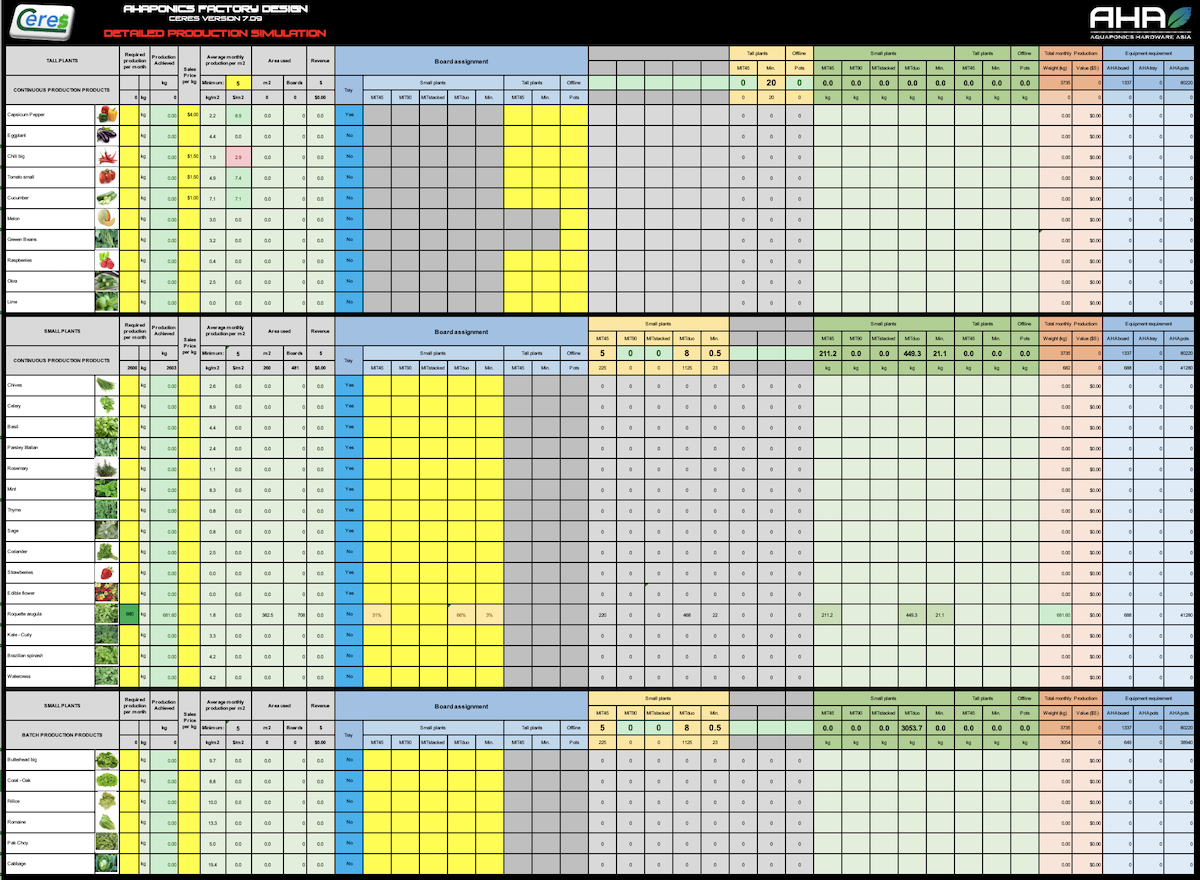

The AHAS proprietary Aquaponics Modeling software computes productivity for various plants. Ceres is continuously updated with actual production data from all our units for each crop. As long as the environment is optimum and AHAS production techniques are followed, you will get the predicted production.

AHAS club members have access to the advanced calculator.

To maximize your unit production, you need to optimize the available growing space utilization. Small plants must be placed at a higher density than big plants. When the plants come out of the germinator, the sponge blocks are placed in pots, and the pots are placed in high-density AHAtrays in the nursery. When the plants get bigger than the pot, they are moved to the MIT production lines at 60 plants per board density. When the plants touch each other, and if we want them to grow bigger, the board is split into two boards at a density of 30 plants per board. Very large plants require the board to be split again at 15 plants per board.

In Ceres, enter the area where you want to allocate the plant production. The required number of boards is automatically calculated. This area is divided into two or three sections to optimize production and Ceres advises the number of weekly seedlings required:

- 60-hole board area

- 30-hole board area

- 15-hole board area

System balance

It usually takes six months to reach a strong and stable ecosystem equilibrium. During that time and sometimes even after, aquaponics lovers sometimes encounter various issues, and we need to be able to deal with them quickly and effectively.

During the first six months, the main objective is to stabilize both fish and plant systems. The fish population should reach 4 to 6 age stages. Each tank hosts a different fish age population. Old fish are harvested in the “old fish” tank. Then, once empty, that tank is populated with young fish, and the next tank becomes the “old fish” tank. Once this cycle is established, your system has five different fish sizes in the fish engine, and the waste products are stable. The fish engine can be generally stabilized in 6 months.

The plant equilibrium is usually much faster to reach since plants are mature in seven weeks. One week in the germinator, two weeks in the nursery, and four weeks in the MIT production lines. But plants must also be harvested continuously and seeded continuously. The best way to organize vegetable production is to allocate an area to each type of vegetable targeted, divide this area into sections, and assign each section a plant age. Plants are harvested in the last section and replaced regularly by the previous section. The density varies in various sections.

Problems and related fixes

In case of any issue, do not rush into drastic actions. Significant changes to plants, water, or fish could upset the ecosystem and balance of your system. Just proceed with minor corrections and monitor the results slowly.

Observe trends. If ammonia increases continuously and exceeds 400 mg/l, you feed by too much. Reduce the fish food quantities. The correct quantity of fish food per day is 30g per board, 60g per square meter. If the emergency case where Ammonia (NH3) exceeds 4mg/l, circulate 30% of the water out and replace it with fresh water.

High Nitrite (NO2) concentrations are generally caused by a rush in starting the unit or a too rapid increase of fish food since there is a lack of nitrifying bacteria in the system. It could also be due to a lack of oxygen getting to the bacteria and the fish.

Always try to maintain the Natural Equilibrium of your Natural Aquaponics ecosystem.

Enjoy and promote your healthy and tasty naturally AHAponically grown veggies.

Contact us in case of a problem.